How to Make Pure Perfume

A Guide for Manufacturers and Custom Fragrance Brands

Do you want to make pure perfume as a manufacturer?

People know pure perfume as parfum. Parfum is the most vigorous and expensive form of scent. For producers alike, comprehending how to make pure perfume at home as a manufacturer may start doors to brand development, and premium perfume profiles.

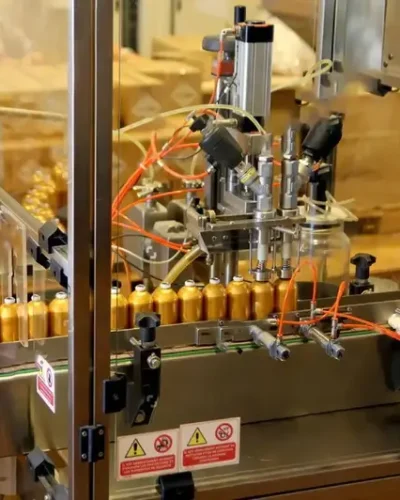

Availability of tools and ingredients can also help create fragrance. In this guide, the manufacturer brand will get the chance for researching small batch perfume manufacturing. It is also designed to make alcohol-free or alcohol-based perfume, utilizing professional methods with MBP Perfume.

What does Pure Perfume Parfum mean?

Pure perfume, or extrait de parfum, bears the top-notch compositions of fragrance oils. And the rest are alcohol or carrier oil. It is a long-lasting fragrance with a richer aroma experience than eau de toilette or body spray.

Does it matter to Manufacturers?

Yes, it is absolutely important for manufacturers for some reasons:

- Luxury positioning: It ensures a high-end feel and better margins.

- Customization: The simple customization makes it easier to blend signature notes.

Alcohol-free options: Alcohol is the primary solvent used to dilute oils. It is a zonal preference for their sensitive skin.

What Manufacturers Need to Make Pure Perfume?

Making pure perfume doesn’t need a full lab setup. Producers can make pure perfume with basic tools and quality ingredients.

Ingredientes

Ingredient |

Essential oils or perfume oils |

Carrier (alcohol or oil) |

Fixatives (natural, like benzoin, vetiver) |

Distilled water (optional) |

Purpose |

Provide scent (top, middle, base notes) |

Dilutes fragrance to a usable level |

Extend longevity |

Helps with blending, if needed |

Tools

- Glass perfume bottles

- Small funnel to facilitate the transfer of liquids

- Dark glass containers for storing blends

- Labels and a notebook for tracking formulas

- Droppers for measuring oil accuracy

- Test strips or blotting paper to test perfumes

Understanding Perfume Notes

To make pure perfume, manufacturing brands or businesses need to layer the fragrance using notes:

- Top Notes: First impression

- Middle Notes: Heart of the perfume

- Base Notes: Long-lasting foundation

A balanced formula frequently needs:

- 30% top notes

- 50% middle notes

- 20% base notes

Use this ratio to guide brabds custom blends or client fragrance development.

Steps to Make Pure Perfume

Let’s get the way with easy steps.

Step 1: Choose Brands Scent Profile

Pick 3–5 essential oils to mix with. Think about the popular blends like:

- Floral scent is generated from rose, ylang-ylang, and jasmine.

- Wood fragrance is created from cedar and sandalwood.

- Citrus is the aroma of lemon and bergamot.

- Oriental scent is off frankincense and amber.

Manufacturers work with expert perfumers or sample libraries to grab custom formulas.

Step 2: Measure the Oils

Use droppers to measure oils based on the note structure. For example:

- 10 drops for top notes or 30%

- 15 drops for middle notes or 50%

- 5 drops for base notes 20%

To blend them for 24 hours, there needs a dark glass container to marry the scent.

Step 3: Add the Base (Carrier)

If the blend is ready, then it is time to add the carrier:

- For oil-based perfume: Manufacturers can create oil-based perfume by using jojoba and fractionated coconut.

- For alcohol-based perfume: As a manufacturer you have to use ethyl alcohol for high-proof.

Bled at 80% base to 20% essential oil to make a pure perfume composition.

Keep the mixture for at least 48 hours, but the standard time is 2–6 weeks for full maturation.

Step 4: Filter and Bottle

After aging the perfume:

- Use test strips or blotting paper to try out the fragrance and balance the formula.

- Pour it into a purified glass bottle with a tight cap or spray head.

- Label with the name, ingredients, and date.

Now producers can use the pure perfume and sell it as part of a unique fragrance.

Why Should Manufacturers Learn This Process?

Though this guide is on how to make pure perfume, the same approach can be applied to small-batch productions or private-label development.

Instructions for manufacturers:

- Prototype new scents without full-scale production

- Train in-house teams in fragrance layering

- Offer workshops or kits for customer engagement

- Create personalized fragrances for retail or VIP clients

In markets like the Middle East, especially in the UAE, customized and oil-based scents are in high demand. A better understanding of method gives manufacturers a creative edge.

Fixatives: Key to Longevity

Popular fixatives include:

- Benzoin resin

- Vetiver

- Frankincense

- Musk

- Myrrh

These are vital components that help hold the scent on the skin. It indicates the extension of perfume’s life with high-quality manufacturing.

Alcohol-Based vs Oil-Based Pure Perfume

Feature |

Evaporation |

Longevity |

Scent Throw |

Sensitivity |

Best For |

Alcohol-Based |

Fast |

Medium |

Stronger |

May irritate some |

Sprays, Western markets |

Oil-Based |

Slow |

High |

Softer |

Gentle |

Roll-ons, Middle East, niche brands |

Pro Tips for Making Pure Perfume

- Store ingredients in dark bottles to preserve quality

- Label everything clearly, including dates and ratios

- Test small batches first before scaling for private labels

- Don’t rush maturation – aged blends have deeper character

- Experiment with layering, like combining oud with florals or vanilla with spice

Manufacturers can use this trial-and-error phase to develop signature scents for clients or house brands.

Turn Small Batch-formulation Perfume into a Business

Want to take your perfume to the next level? Here’s how to scale responsibly:

- Standardize recipes using digital tools or lab notebooks

- Source ingredients from reliable wholesale vendors

- Develop a brand identity with sustainable packaging

- Create starter kits or gift boxes for retail

- Offer custom blends as part of business service model

Solid knowledge of how to make pure perfume becomes brands’ foundation for custom perfume manufacturing and market-ready products.

Ready to create your signature scent?

Contact MBP Perfumes today for expert custom perfume manufacturing. Let’s turn your fragrance vision into reality!